N.B. family farmers win coveted Master Breeder award

/by George Fullerton

Brothers John and Derek Robinson of Hazelhill Farms in Sussex, N.B., have brought their Holstein herd into a rare and honoured position by receiving Holstein Canada’s 2021 Master Breeder award in January.

Hazelhill was one of only 19 farms across Canada to receive the award and one of only three in Atlantic Canada (the other two were Lindenright Holsteins and MacGregor Dairy Farm, both of Nova Scotia).

Holstein Canada has presented the annual award since 1929 to recognize purebred breeders who’ve built a herd with a combination of high milk production, outstanding conformation, strong reproduction, good health, and longevity.

The award is based on a points system, with breeders earning points for both milk production and classification of registered cows.

Hazelhill milks in the range of 250 cows, which puts them in the highest herd size category assessed for the Master Breeder award.

John and Derek followed the leadership and inspiration of their parents John Sr. and Elizabeth. In 1961, in his early 20s, John Sr. took over management of Hazelhill following the death of his father Ernest.

John Sr. and Elizabeth started with a 20-cow milk line. In 1972, they built one of the first free-stall barns in southern New Brunswick. By the early 1980s, they were milking around 100 cows. It was during John Sr.’s tenure that the Hazelhill prefix and the foundation of the purebred herd were established.

John Sr. became a noted leader in the dairy and overall agriculture sectors, as well as serving on numerous volunteer boards in Sussex. He served as director and chair of the New Brunswick Milk Marketing Board and as president of the New Brunswick Federation of Agriculture. He was inducted into the New Brunswick Dairy Hall of Fame in 1998 and the Atlantic Agricultural Hall of Fame in 2009.

COMFORTABLE COWS

In 2007, the Robinsons built their current free-stall barn with a double-12, rapid-exit milking parlour.

“Donnie Anderson is a dairy consultant based in Sussex and he helped a lot with the design of the current barn,” said John. “We had considered sand bedding when we were planning the new barn, and because at the time wood shavings were hard to obtain, we went with sand. The sand bedding provides great cow comfort, and it has made a major impact toward achieving the Master Breeder award.”

He added, “Sand is great for cows, but it is hard on equipment. We had to learn to work with it.”

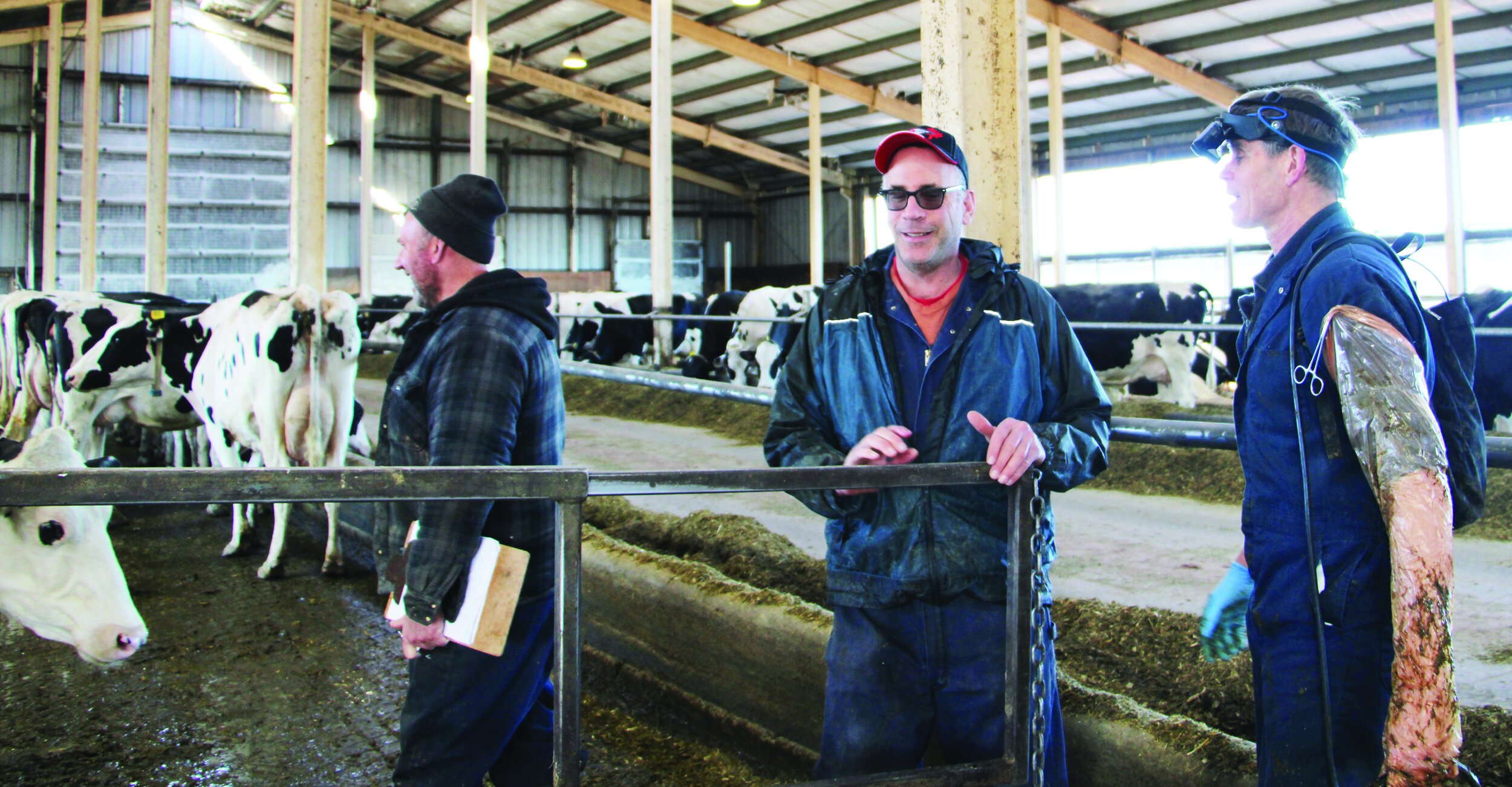

A visit to Hazelhill Farms happened to coincide with Dr. Marc Verschoor’s herd health check.

“This is probably the most comfortable barn for the cows in New Brunswick,” said the veterinarian. “They have large, roomy stalls bedded with sand, which is very comfortable for the cows and very healthy as well. The barn has excellent ventilation with thermostatically controlled curtain walls and an open peak.”

Verschoor added that the comfortable barn and good management contribute to the high production and longevity of the Robinsons’ cows.

Calves born at Hazelhill spend their first 24 hours with their dam, then go on bottle feeding for several days. After that, they advance to a mob feeder. After a couple of weeks in the free-stall barn, they move to the calf barn for a couple of months.

Depending on their size, heifers are bred to calve at 22 or 23 months of age. All cows are classified during their first lactation and again in their second lactation.

“In their third lactation, they are eligible to classify as excellent,” said John. “Some make that classification. Some don’t.”

He added, “We have some cows that continue to make high production in their eighth lactation. We see most of our cows produce well for four to six lactations. Older cows milk a lot better than heifers, so those older cows pay for themselves.”

FEEDING AND BREEDING

As the herd size increased, the Robinsons acquired additional land as well as rented land to produce feed for their herd. They currently own in the range of 500-600 acres and continue to rent land.

They grow about 300 acres of corn every year. “We keep up to date on growing trials and continually test new seed varieties to see how they work in our region,” said John. “Corn breeding technology advances very quickly and we adapt to keep in the game.”

In their crop rotation, land in corn for a couple of years is followed by a forage crop, often an Atlantic dairy mix.

“We often add extra alfalfa into the seed mix,” said John. “Some ground is a lot better suited to growing alfalfa. Results and longevity in the sward varies with soil types.”

Sean Moffett has been providing genetics and artificial insemination (AI) services for the Robinsons for about 30 years, initially with EastGen and more recently with Select Sires.

Both John and Derek expressed their admiration for Moffett’s knowledge of Holstein genetics and his AI skills.

“In his work, Sean sees a lot of herds and cow families, and he has accumulated a great deal of knowledge,” said Derek. “He brings that knowledge and awareness to our farm, and we take it into consideration when we make our breeding decisions.”

“The Robinsons tend to use bulls that they really like – fairly heavily,” said Moffett. “Some farmers like to use a different bull every month. Sticking with fewer bulls tends to build consistency in the herd. When selecting a sire to compliment a cow, we give considerable attention to udder, feet, and legs and rump.”

He added, “Generally, the three of us (he, Derek, and John) discuss bull selection and at the end of the conversation, we come to an agreement on the sire. The Master Breeder award shows that we must have been doing a pretty good job.”

BREAKFAST IN THE BARN

When the new free-stall barn was built in 2007, John and Derek wanted to keep their father involved in the farm and decision-making, but they also wanted to see him slow down on his physical contributions. They decided to build a large kitchen in the barn and assigned John Sr. the job of making breakfast for the entire crew. The communal meal provided the opportunity to plan out the day’s work and review any farm-related issues.

Shortly after John Sr. died in 2016, Moffett found himself dropping his teenage son off at his work in Sussex at 6:45 a.m. and began the habit of starting his AI day by dropping in on the Robinsons’ morning milking. Instead of watching the milking and making a nuisance of himself, Moffett assumed John Sr.’s duty of preparing breakfast for the Robinson crew. His culinary skills, like his AI skills, have sustained him in the position as breakfast chef.

Hazelhill employs two full-time employees and a couple of part-time employees. John’s wife Nicki maintains an active role working in the barns, and Derek’s wife Angela provides administrative and office management support.

“We have a lot of our extended families working with us,” said Derek. “Our success is very much dependent on a team effort.”

Asked about the challenges of managing a comprehensive operation with a sibling, Derek said that while he and John have days with disagreements, they work well together overall.

“We are very different personalities, which may help us get along quite well,” said Derek. “We are both committed to the end game. When I am away from the farm, I am confident that John is managing things effectively, and I figure he feels the same when he is away from the farm.”